Taking into consideration the actual site requirements.

Proper planning is essential for installing a wall-mounted LVAC board. This guide outlines the key considerations to help contractors ensure a smooth and efficient process, whether pre- or post-tender.

Note if you have an on site AP then moving of the items is the responsibility of the site contractor. This would have been established at tender time. We will at RAMS time submit dimensions and sizing information for your AP to ascertain the task at hand.

LOLER / PUWER and RAMS will be submit prior to site attendance so all parties are aware of the task or tasks to be executed.

Installation Location and Accessibility

The installation method depends on the board’s location and site accessibility. We know sites vary and as such so do the challenges. The short of this page is we care about human life. Getting the job done safely and efficiently is of paramount importance.

Ground-Level Installations

For ground-level installs, no specialised lifting (e.g., HIAB) is typically required. Our team will unload and move the board parts into the building, ready for fitting to the wall. If the site is not a standard ground entry / door straight into fitting room please read on for additional considerations.

Building Construction Type

The type of building impacts the complexity of the installation:

Brick Buildings

Brick buildings generally allow for straightforward installation, provided:

- The wall is flat and free from protrusions.

- There are no health and safety risks, such as asbestos or structural obstructions or considerations. Some buildings are existing and sometimes older in nature. Asbestos has been a factor in some previous projects.

- The moving route is at ground level.

- There is sufficient space for us to move the parts into position. And winch / support them.

- The area is free from obstructions.

If these conditions are met, our team will unload the board and transfer its parts into the room for fitting. Contractors must ensure that wall surfaces are ready for installation before our arrival.

Point is case above illustrated the site manager relayed sufficient photographs ahead of time. This allowed us to plan the route – lift and install. Providing us with the relevant information is key for us to all identify hazards ahead of time. Be safe, furnish us with the facts and we can all act as a team to get this across the line.

Prefabricated Buildings (Prefab)

Prefab buildings require additional preparation. Contractors must install a Unistrut framework or equivalent before our team arrives. This framework is necessary to support the centre fixings as detailed in the General Arrangement (GA) drawings.

The Unistrut must be in place prior to the us arriving on site. Failure to do so could result in an abortive labour charge. Depending on the geographic location this could be a costly mistake.

Route and Wall Space Requirements

To ensure a smooth installation, the route from the unloading area to the installation site must be:

- Clear of obstructions to allow easy movement of components.

- Free from hazards, such as narrow or blocked pathways.

The wall space designated for the LVAC board must be:

- Flat and level to enable proper mounting.

- Clear of protrusions or surface irregularities that could interfere with secure fitting.

Weight and Dimensions

We provide weight and dimension details with the GA drawings. Contractors must confirm that the wall or supporting structure can accommodate the load to avoid delays. Plus accommodate the board in its entirety.

Special Handling and Site Requirements

Site-specific conditions may necessitate additional services, which involve extra costs:

Elevated / First-Floor Installations

For boards installed on the first floor with staircases exceeding three steps, a HIAB service is used to unload parts onto the landing.

If no AP service is required or available and the route is clear and simple, our team will use LOLER-certified equipment to move the board and a winch system for final fitting.

The definition of simple referring to the switch room being in close vicinity to the landing. Should the route from landing to final switch room be at multiple levels or require multiple hazards to to be maneuvered then an AP / Skate team would need to be employed at extra cost. This would have been established at tender time. If not additional quotations would be submit to overcome the H&S challenges.

Having had the switch board parts lowered to the the landing we then lay the board part onto a wheel base and navigate the part through the doorway. This method is used for both parts of the WM (Wall Mount) board. Once in the room we use a LOLER certified winch lift to elevate the board and fit the to Unistrut framework (See prefab buildings above).

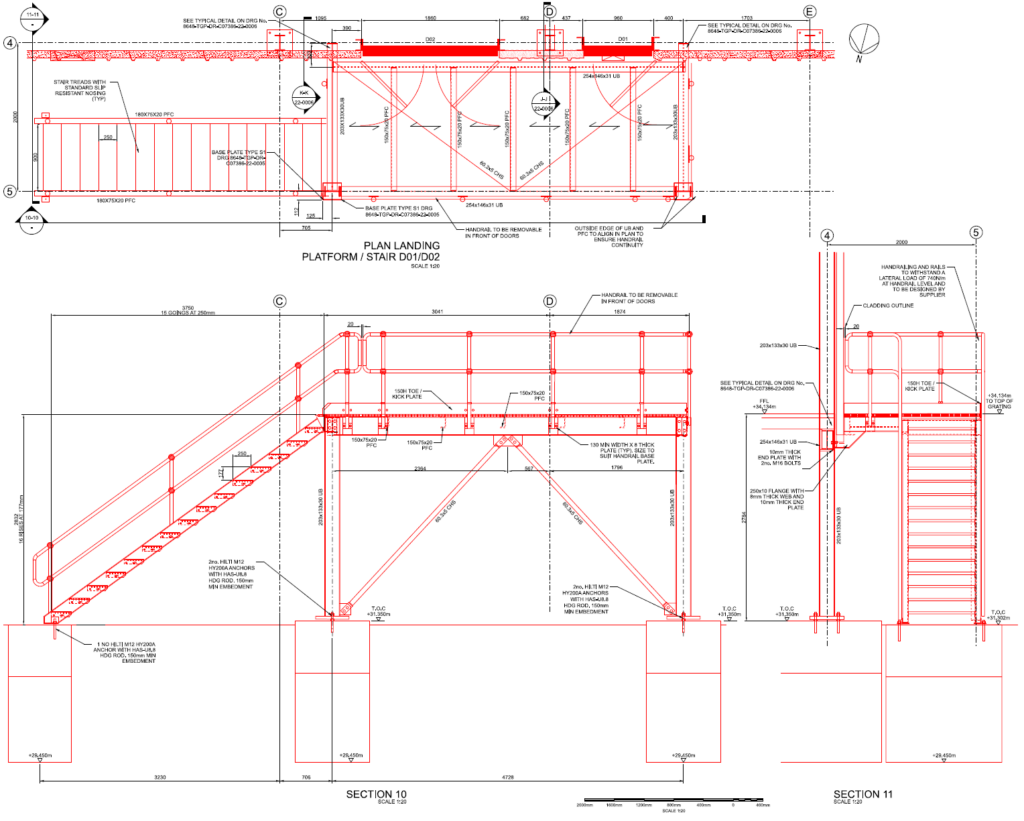

Below shows in reality a loading space for Hiab to lower. Our engineers would then unhitch and move parts into room. This would be documented in our RAMS (Risk Assessment Method Statement). This footprint may be larger on your project, the contractor or PM would have been expected to submit building plans at the time of tender.

Appointed Person (AP) Survey

For hazardous or restricted sites, an AP survey is required to assess the risks and plan the move. Based on this survey, a specialist move team may be assigned. Both the survey and the team incur additional costs.

These scenarios, while uncommon for wall-mounted boards, depend on site-specific conditions and should be clarified at the tender stage. If your site has an AP then not an issue, we can supply the AP with the boards details for assessment.

Specialist Handling due to route.

In addition to a standard Hiab service a machine skate team may be required for components, additional charges will apply. If the route is unusual or arduous then it generally needs a specialist team. As a contractor we will need to know these factors for costing. This page is primarily for approaching contractors for consideration and scope.

Pre-Tender and Site Preparation Checklist

To avoid delays and unexpected costs, contractors should:

Pre Tender Submission:

Confirm any site-specific hazards, such as asbestos or restricted access.

Identify if AP services or specialised handling will be required. Or if the site has an appointed AP for moving tasks.

Before Switchgear Supplier Arrival (Prefab Buildings) At point of delivery:

Wall Mount Boards require a Unistrut framework to mount the board. Please Ensure Unistrut or similar frameworks are installed for prefabricated type buildings. Failure to do so can incur abortive site attendance charges. Centre dimensions are submitted at the point of tender and at the point of RAMS.

Key Points for a Successful Installation

- Ground-level installs: Generally no HIAB required; straightforward move. Unless route is complicated or prone to having non standard walkways. Then we look into possibly Hiab / AP and skate team.

- Brick buildings: Straightforward if no health and safety risks (e.g., asbestos) are present, and the wall is flat and clear. And the board is at ground level. If first floor we take it on a case by case basis. Hiab could be applicable.

- Prefab buildings: If elevated then landing is to be safe and sufficient for landing parts. Rails fitted, obstructions negated (Slips / trips and falls). Unistrut framework erected prior to site attendance.

- Hazardous/restricted sites: AP survey and specialist handling will be required.

By addressing these considerations early, contractors can ensure a safe, efficient, and compliant installation process while avoiding unexpected costs. By the time the board is to be delivered we should have established the safe method of execution of the task.

Install Time – 110VAC Required – Why?

Part of out testing procedure is having local 110VAC local to the board having fitted to the wall. The reason being we are required to flash test composite board in order to record our values.

Unfortunately a flash tester is not the same as an insulation resistance tester that works off batteries. We do require the obligatory 110VAC supply that a construction site should have available.

This text is to inform the site manager and allow you time to if you haven’t already got 110VAC into room. We generally turn up with a 50 meters reel, so long as we can reach a spider point or similar thats fine.

Should 110VAC not be available on the day the test cannot be carried out. Any return visits due to lack of site facilities are charged at applicable day rate for the region. This will be passed onto the principle contractor.

Cable Size and Direction

The main premise to consider is if you have a TOP or BOT biased board. Meaning which direction do your incoming cables come from? Consider your cable entry and direction plus the size of conductors you are terminating. This should all be bottomed out pre tender. And is not relevant to the actual install day when we visit.

Additional Reading Material

Health & Safety Considerations for On-Site Delivery of Switchgear by Hiab

The Vital Role of the Appointed Person (AP) in Safe Lifting Operations

What Is LOLER and When Does It Apply? Should you care? YES

What Is PUWER and Why Is It Essential for Your Business?

Disclaimer:

The information provided on this site is for general informational purposes only and may not reflect the most current regulations or standards. Legislation, industry guidelines, and best practices can change over time, and it is the user’s responsibility to research and ensure compliance with the latest requirements for their specific situation. Always consult a qualified professional for advice tailored to your project or application.